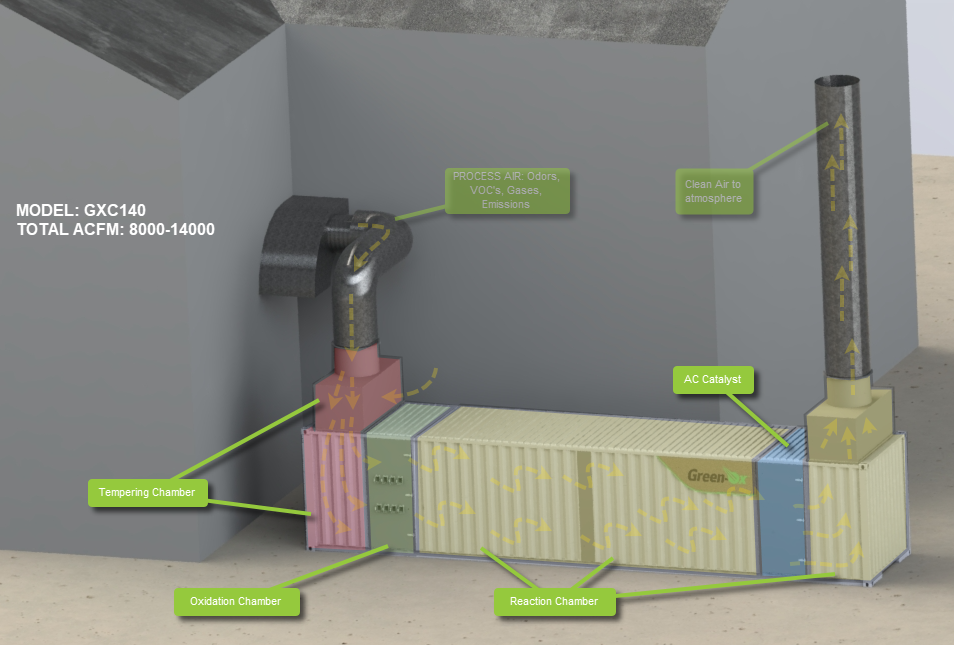

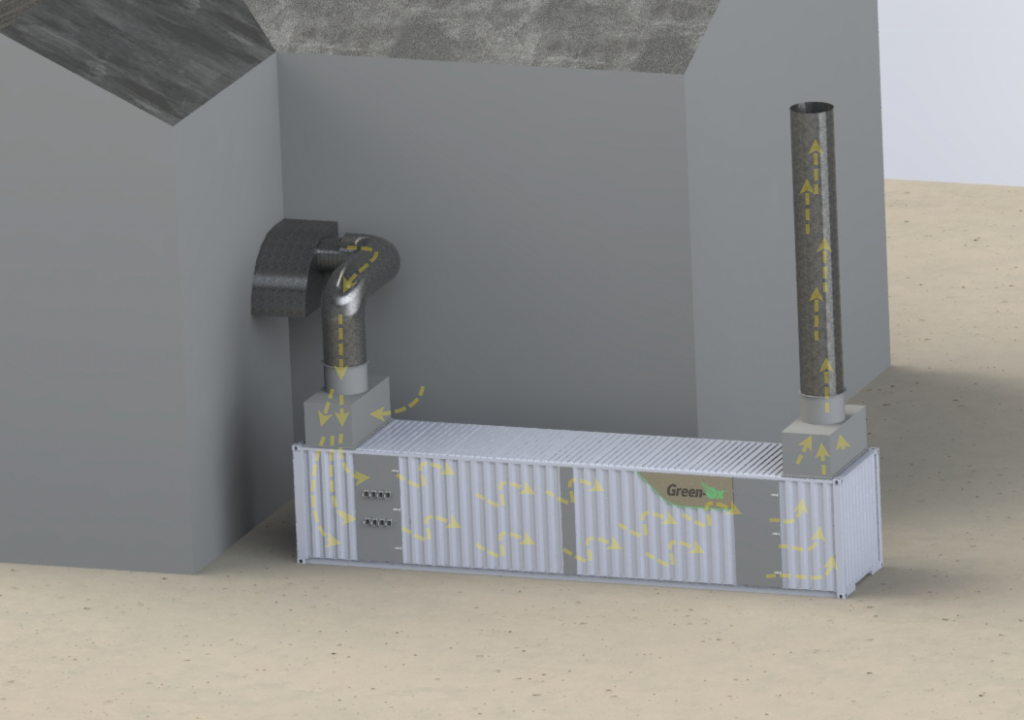

There are two main considerations when designing the air treatment system: (1) Your Desired Outcome and (2) the Profile of your Air (temps, contaminates, humidity, flow rates etc. First, we establish the end-goal by identifying the targeted emissions that need to be controlled, and at what level. Then we Analyze all factors of the Process Air per applications, including air-flow (CFM), air temperature, Emission Gases, VOC’s and PM load, humidity etc. From there we engineer a guaranteed solution.